Rotational molding of solar bracket

Solar Plastic Molding

Solar Rotational Molding is an excellent way to close the loop and reuse post-industrial and post-consumer plastic for new products. Especially important is our ability to recycle materials in the field – near landfills and beaches – without

FAQs | LightManufacturing Inc.

Rotational molding, and Solar Rotational Molding (SRM) can use a variety of plastics – including virgin (new) material, and recycled material. Plastics made from fossil fuel sources have many

Effect of different combinations of bracket, archwire and ligature

The bracket design, archwire, and ligation method were regarded as key factors affecting RS.3,13,14 Other studies have not confirmed the superiority of self-ligating

Solar Plastic Molding: The Key to Improved Water Security and

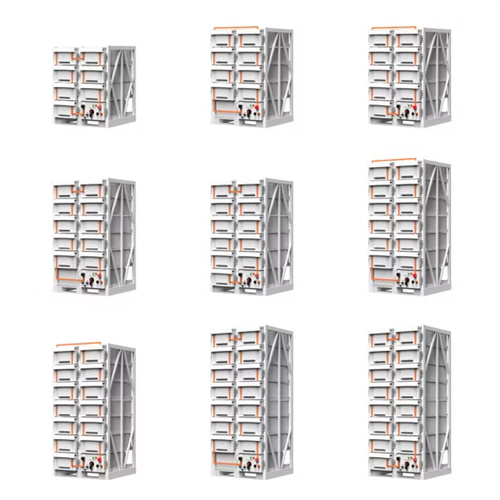

The solution is Solar Rotational Molding. This recently developed technology (patents and other IP information here) packs an entire molding factory into a single shipping container, and can

Comparison | LightManufacturing Inc.

Solar Rotational Molding (SRM) is unique among sustainable manufacturing processes in that it highly competitive with the traditional process it displaces without subsidies. The table below

Rotational Molding | Advantages of Rotational Molded Plastics

Rotational molding is a manufacturing method that produces parts fabricated from polymer resins, which can offer excellent chemical and environmental resistance. components such as

Solar-powered solution developed for heating rotational molds

The company, called LightManufacturing (San Luis Obipo, CA), is itself a rotomolding processor. The company predicts its "Solar Rotational Molding" (SRM) systems,

Common Challenges and Solutions in Rotational Molding

Renewable Energy: Incorporating renewable energy sources, such as solar or wind power. Waste Reduction. Reducing waste is crucial for environmental sustainability:

LightManufacturing Inc. | Heliostats and Sustainable

We also make solar thermal plastic molding systems. Our SRM (Solar Rotational Molding) solutions are turn-key "Factory in a Box" systems that use heat from heliostats to melt plastic and make useful products like water tanks, boats,

Sustainable plastics manufacturing with solar rotational moulding

[Courtesy of Interplas Insights]LightManufacturing is a company innovating in sustainable plastic moulding with its Solar Rotational Moulding (SRM) process. Unlike traditional methods that

Solar Rotational Molding Introduction

LightManufacturing LLC introduces Solar Rotational Molding - a sustainable approach to plastic molding, that''s competitive with traditional processes without

Developed World | LightManufacturing Inc.

Developed World Solar Rotational Molding is the only solar energy application which is competitive with a traditional manufacturing process, without subsidies. Because SRM''s initial

California firm supplies solar-powered rotomolding units

Founded in California in 2010, LightManufacturing supplies solar-powered rotomolding machines. Each of the machines, known as solar rotational molding systems (SRMs), rely on energy captured by heliostats —

Top Floating Solar PV Mounting Manufacturer in China

Best floating solar mounting manufacturer in China, Topper offers top quality solar floating PV mounting systems with HDPE plastic blow molding plant. We use the most state-of-the-art

LightManufacturing uses solar power to rotomold off

The sun-tracking mirrors concentrate solar-thermal energy on a rotational mold. The heat from the sun directly warms the mold, melting the plastic with zero greenhouse gas emissions at zero fuel

Rotational Molding Process

The rotational molding process starts with a good quality mold that is placed on a molding machine that has a loading, heating, and cooling area. To rotationally mold parts more than

About Solar Plastics | Custom Roto Molding Team

Since 1964, Solar Plastics has been engineering custom roto molding plastic parts for our global clients in a multitude of markets including agriculture, construction and chemical storage.

The Process and Advantages of Rotational Moulding

Rotational Moulding Rotational molding is a process that produces hollow products using cast aluminum or steel molds, allowing for affordable production for small manufacturing runs. This

Rotational Molding: Advantages and Disadvantages

The Pros and Cons of Rotational Molding. The resin in rotational molding is melted into the mold walls, as opposed to being driven into the walls by pressure, like in blow molding or

A Guide to Rotational Molding

Advantages of rotational molding Rotational molding offers significant advantages when compared with other molding techniques or thermoforming: costs for molds and tooling are

Solar Plastic Molding | LightManufacturing Inc.

LightManufacturing''s patented SRM (Solar Rotational Molding) process uses sun-tracking mirrors called heliostats, to concentrate solar energy on a rotational mold. We have developed a uniquely capable heliostat, called the H1. Heat

Custom Metal Inserts for Plastic Rotational Molding | | Rotaloc

We manufacture custom metal inserts for plastic rotational molding applications, including rotomolding inserts for DEF tanks, filters, pumps, & more. - (303) 948 - 5434. About Us;

Rotational Molding: Everything You Need To Know

Rotational molding also known as roto molding is an advanced molding technique, used to make hollow parts without the application of pressure. It''s a casting process

Rotational molding: A review of the models and materials

Rotational molding (RM) is a polymer processing technique that possesses a number of advantages such as lower residual stresses in parts, simpler ma- cently by solar energy [4].

Plastic Rotational Molding – The Complete Guide

Steps of Rotational Molding. More Resources: Roto Molding; Roto Molding Technique ; Rotational Molding Process ; Advantages of Rotational Molding. The following are

What is Rotational Molding? An In-Depth Guide to

By the end, you''ll have a comprehensive understanding of what rotational molding is and why it''s a preferred choice in various industries. The History of Rotational

Rotational molding: A review of the models and materials

This article surveys recent and not so recent literature in the field of rotational molding. The mechanisms of heat transfer, sintering and bubble removal are evaluated; as are

Rotational Molding Design Guide | Rotomolding | Gregstrom

Published by the Association of Rotational Molders (ARM), this downloadable PDF describes the advantages of rotational molding, how rotomolding works, the different molds that are used,

Direct Solar Heating for Rotational Molding Enables Feedback

Because solar rotational molding reflects radiation from the sun directly onto the outer surface of the mold, most of the heat is directed just where it is needed. "What''s crazy is

6 FAQs about [Rotational molding of solar bracket]

What is solar rotational molding?

LightManufacturing’s patented Solar Rotational Molding (SRM™) systems use heat from the sun to safely mold useful products like water tanks . By eliminating the need to burn fossil fuel we make the molding process much cleaner and lower-cost. Zero greenhouse gas emissions, no particulate pollution, no carbon monoxide.

How does solar plastic molding work?

Our solar plastic molding systems use free solar heat from heliostats to make plastic parts, instead of expensive fossil fuel. Our Solar Rotational Molding (SRM®) factories are complete systems – just add molds and plastic. Energy for mold rotation is supplied by integrated photovoltaic panels.

How does rotational molding work?

In rotational molding, rigid, resilient hollow bodies are formed by powdered plastic material in heated molds, which are rotated simultaneously in two planes perpendicular to each other. melt on the inner surfaces of the hot molds and fuse in layers until all the powder is fused and the desired end product and wall thickness is obtained.

What is solar plastic shredding?

Related Product: Solar Plastic Shredding, for waste processing and densification. LightManufacturing builds and operates self-contained Solar Rotational Molding systems which make large plastic products like water tanks without burning fossil fuels. This reduces the product cost and eliminates greenhouse gas emissions.

What is a rotational mold?

The most important property of a rotational mold is that its interior surface has to be completely non-porous. Cast aluminum molds are by far the most frequently used molds in the rotomolding industry. Most parts that are small- to medium-sized are molded with a cast aluminum mold.

What is a standard wall thickness for rotational molding?

Wall thicknesses can range from 1/32 inch to 1 inch (0.8mm to 25mm). Most resins used in rotational molding are powders ground to 35 mesh and ranging in diameter from 74 microns to 2000 microns. Rotational molding permits production of a countless number of fully or partially closed items.

Related Contents

- High-end solar bracket integrity service

- Four Seasons Moge Solar Bracket

- Water meter well solar tube installation bracket

- Solar thermal power generation concentrator bracket

- Inner roll groove of solar photovoltaic bracket

- High-rise solar bracket warranty

- Shangfan solar bracket forming machine

- Spring Rain Solar Bracket Installation Diagram

- D-Link solar bracket installation

- Customs code for solar photovoltaic bracket

- Residential building solar bracket

- Solar Camera Bracket Manufacturer