Photovoltaic panel production line management

100MW Solar panel production line

100MW solar panel production line composition: Production line specification: 1. 100MW module production line (1). 2. Beat: ≤45 seconds/block. 3. Type of panel produced: conventional full

Photovoltaic panels: operation and electrical production

Example calculation: How many solar panels do I need for a 150m 2 house ?. The number of photovoltaic panels you need to supply a 1,500-square-foot home with

Solar Panel Production Line Provider

450MW Turnkey Solar Panel Production Line. Cycle: 135 PCS/hour; Operators: 31operators per shift; Floor Space: 4050 m² Machines for the production line are built with materials procured from strict supplier management and quality

Quality Control and Testing for PV Solar Modules

CEA''s inline production process monitoring sends experienced quality control engineers to the manufacturing facilities during production of your product to verify BOM compliance, inspect manufacturing conditions, verify calibration of

Mexico''s Solarever commissions new 500 MW solar panel production line

From pv magazine Mexico. Mexican solar module manufacturer Solarever has commissioned a new 500 MW solar module production line at its factory in Tecomán,

End-of-Life Solar PV Panels

The report, End-of-Life Management: Solar Photovoltaic Panels, is the first-ever projection of PV panel waste volumes to 2050 and highlights that recycling or repurposing solar PV panels at

(PDF) An overview of solar photovoltaic panels'' end

This review focused on the current status of solar panel waste recycling, recycling technology, environmental protection, waste management, recycling policies and the economic aspects of recycling.

End-of-life solar photovoltaic panel waste management in India

Presently, India is in the stage of installation of solar photovoltaic panels and no focus is being given towards the impending problem of handling solar waste. The absence of

Quality Control in A Solar Panel Production Line

Why is quality control in a solar panel production line important? Quality control ensures the PV panels manufacturers produce are reliable, efficient, and safe for use. In this article, we will discuss how to implement

Solar Panel Production Line Manufacturer, Solar Panel Making

Solar Panel Production Line Supplier, Solar Panel Making Machine, Solar Machine Manufacturers/ Suppliers - Focusmain Intelligent Technology (Jiangsu) Co., Ltd. Menu

Solar Cell Making Machine,Automatic Solar Panel Production Line

Supo(Xiamen)Intelligent Equipment Co.,Ltd Engaged in Turnkey solution for solar panel production line and raw material supply chain management Address: G, Room 417, 66 Haijing

Specialist In Solar Panel Production Line

Radiant PV Solar focus on manufacturing solar panel production line in solar industry more than 12years. MORE . 12. Years Of Experience . 10 GW+. Production Installed. 80 + Projects . 100

Solar Panel Production | Solar Cell Manufacturing | LA Solar

The solar systems industry is the growing production of solar panels. Certifications are guarantee of the quality of our solar panels Cutting the crystalline cells of the solar panel into 1/2, 1/3

PV Module Automation Production Line

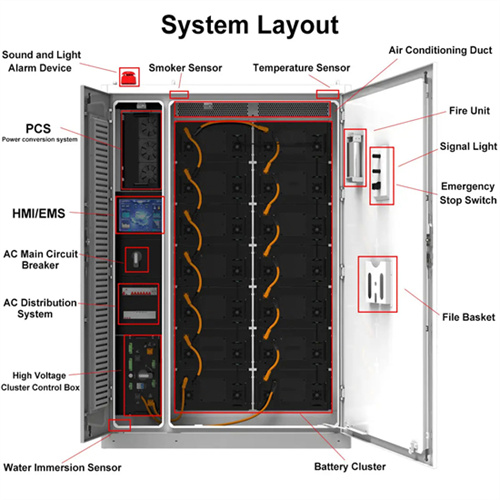

Introduction of Solar Panel Production Line The control and supervision system consists of two parts: the on-site photovoltaic production line centralized management system and the

An overview of solar photovoltaic panels'' end-of-life material

Worldwide, the recycling of PV products requires producers to employ waste management techniques or employ the service of companies or non-profit organizations and

Solar Photovoltaic Manufacturing Basics

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current (DC) electricity, which is what a solar panel generates, to alternating current

Solar Manufacturing Cost Analysis | Solar Market

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV

How to Write a Solar Production Business Plan

A good business plan should include the following elements: 1. Executive summary: a brief overview of the business plan, including a summary of the company''s

Executive summary – Solar PV Global Supply Chains

The world will almost completely rely on China for the supply of key building blocks for solar panel production through 2025. Based on manufacturing capacity under construction, China''s share

Complete turnkey lines for pv panel production

As a European technology leader, Ecoprogetti Srl supplies highly efficient equipment for the photovoltaic industry since 1998. The product range includes single equipment for PV Panel

End-of-life management: Solar Photovoltaic Panels

This report is the first-ever projection of PV panel waste volumes to 2050. It highlights that recycling or repurposing solar PV panels at the end of their roughly 30-year lifetime can unlock an estimated stock of 78 million

Best solar monitoring systems for 2024

Types of solar panel monitoring systems. The bottom line when it comes to solar monitoring. No matter what solution you choose, solar monitoring has two basic functions: making sure

Solar Panel Production on Line Analysis

Solar Panel Production on Line Analysis. April 2024; Authors: Ajay Lal D. Amrita Vishwa Vidyapeetham; Download full-text PDF Read full-text. Download full-text PDF. Read

Executive summary – Solar PV Global Supply Chains

The solar PV industry could create 1 300 manufacturing jobs for each gigawatt of production capacity. The solar PV sector has the potential to double its number of direct manufacturing jobs to 1 million by 2030. The most job-intensive

PV MODULE MANUFACTURING SOLUTIONS

applies a management syste m in lin e with th e above standard for th e fo lowin g scope 300mw pV modUle prodUction line complete solUtion For pV modUle manUFactUring G L

625 MW Photovoltaic Panel Production Line

When selecting a photovoltaic panel production line, J. v. G. technology GmbH stands as the ideal choice with its 625 MW PV Production Line - Classic. Key considerations such as technology,

Photovoltaic Modules Manufacturing | Solar

IOCCO, through the establishment of the brand Ingenious Power, offers equipment worldwide to assembly photovoltaic modules by the reverse engineering of systems, ensuring outstanding production and quality

Solar Panel Production Line, Semi-Auto Laminator, Full-Auto

Qinhuangdao Shuogu Photovoltaic Science & Technology Co., Ltd: SHUOGU Photovoltaic is committed to providing a variety of photovoltaic equipment and designing professional solar

Solar Panel Production Line

Professional Solar Panel Production Line manufacturer, We provide solar panel making machines, solar panel assembly lines, solar panel manufacturing equipment, ODM, and OEM directly from the factory. 5MW-200MW solar

100MW SMART Production Line for Photovoltaic Panel

Ecoprogetti offers 75MW Production Line - Photovoltaic Panel. Ecoprogetti''s production lines are configured to accommodate two primary panel sizes: 2.3×1.4 m for residential use, and

Cost Breakdown of a Solar Panel: From Manufacturing to Market

The energy-intensive nature of these processes, along with the high purity requirements, makes silicon a significant cost factor in solar panel production. Metals Silver is

6 FAQs about [Photovoltaic panel production line management]

Why is maintenance management important for PV power plants?

Therefore, maintenance management is essential for reliable and effective operation of PV power plants, ensuring uninterrupted system operation and minimizing downtime. Compared to well-established technologies such as hydro, thermal, and wind, the O&M processes for PV systems are not yet fully structured in many operating companies .

What makes a successful PV maintenance program?

A successful maintenance program seeks to minimize failures, maximize production uptime, and reduce production loss through timely interventions. Once a maintenance strategy is determined, the focus shifts to scheduling, presenting an optimization challenge to ensure continuous and reliable operation of the PV system.

What is solar photovoltaic (PV) power generation?

Solar photovoltaic (PV) power generation, with abundant irradiance, stands out among various renewable energy sources. The global deployment of solar energy has experienced significant growth in the last 10 years. In 2022, a significant 231 GWdc of PV capacity was installed globally, resulting in a total cumulative PV installation of 1.2 TWdc .

How has global solar PV manufacturing capacity changed over the last decade?

Global solar PV manufacturing capacity has increasingly moved from Europe, Japan and the United States to China over the last decade. China has invested over USD 50 billion in new PV supply capacity – ten times more than Europe − and created more than 300 000 manufacturing jobs across the solar PV value chain since 2011.

Is polysilicon a bottleneck for solar PV?

Global capacity for manufacturing wafers and cells, which are key solar PV elements, and for assembling them into solar panels (also known as modules), exceeded demand by at least 100% at the end of 2021. By contrast, production of polysilicon, the key material for solar PV, is currently a bottleneck in an otherwise oversupplied supply chain.

Do photovoltaic systems need maintenance?

The expansion of photovoltaic systems emphasizes the crucial requirement for effective operations and maintenance, drawing insights from advanced maintenance approaches evident in the wind industry. This review systematically explores the existing literature on the management of photovoltaic operation and maintenance.

Related Contents

- Which line of the photovoltaic panel is the positive pole

- How long is a dotted line on a photovoltaic panel

- Homemade photovoltaic panel bracket production

- Photovoltaic panel production materials

- Photovoltaic panel shrapnel production

- How much does it cost to put a small yellow line on a photovoltaic panel

- There are several brands of photovoltaic panel production lines

- Photovoltaic panel line construction process

- Cutting equipment for photovoltaic panel production

- Yingli photovoltaic panel production process drawing

- Photovoltaic panel enhancement artifact production tutorial

- Photovoltaic panel line direction